High-Precision Injection Mold Design Services in Shanghai – Medical & Industrial Tooling

Mold design

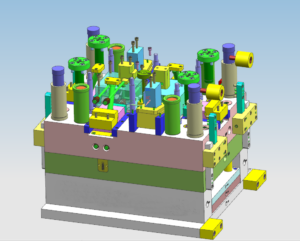

Professional Injection Mold Design Services: From Concept to Production

Based in Shanghai, China, we specialize in custom injection mold design, rapid prototyping, and high-volume manufacturing. Our team bridges the gap between a creative concept and a manufacturable product, ensuring high quality at a competitive price.

Why Choose a China-Based Engineering Partner for Your Mold Design?

Many clients approach us with only a physical sample or a rough sketch. Our job is to turn those “Design Keys” into reality:

Reverse Engineering: We refine and optimize existing samples to improve structure and reduce costs.

DFM (Design for Manufacturing): We analyze your 3D models to ensure they are optimized for the molding process, reducing future tooling risks.

Cost-Effective Innovation: We help you achieve premium aesthetics and functionality without unnecessary investment.

Advanced Engineering & Software Expertise

Our design team is proficient in industry-leading 3D software to ensure 100% accuracy:

SolidWorks & UG (NX): For complex structural design.

Pro/Engineer (Creo) & Catia: For high-end industrial surfacing.

Moldflow Analysis: We simulate the injection process to predict flow, cooling, and potential defects before the steel is cut.

1. Avoiding Sink Marks

Sink marks are surface depressions caused by localized shrinkage.

The Fix: Maintain consistent wall thickness.

Pro Tip: Gate size and location are crucial. A gate that freezes too early prevents proper packing. We optimize gate placement to ensure the cavity is fully packed.

2. Preventing Warpage

Warping is caused by uneven internal stress during cooling.

The Fix: Minimize transitions between thick and thin sections.

Pro Tip: Use ribs instead of increasing wall thickness. Rib thickness should not exceed 60% of the main wall thickness to prevent sink marks on the opposite side.

3. Optimizing Draft Angles

To prevent parts from sticking and to eliminate ejector marks:

Standard: A draft angle of 1° to 2° is usually required.

Texture: If the surface is textured, a larger draft angle is necessary to protect the finish.

Specialized Capabilities: Medical & Automotive Mold Excellence

Our engineering team brings decades of combined experience to two of the most demanding sectors in the industry: Medical Devices and Automotive Components. We understand that these sectors require more than just a mold.