Why precision injection molding is difficult?

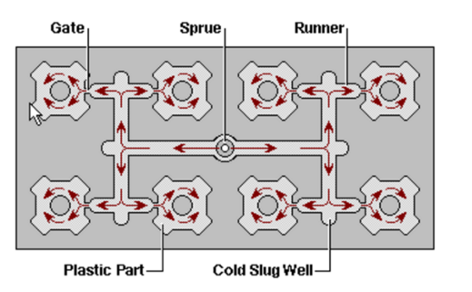

Injection molding:

it is an injection molding method. The injection molding method has the advantage of production speed, high efficiency. It can realize automation operation, breed of design and the color is much, can shape by Jane to numerous. It can from big to small size, and precise in dimension and product upgrading. Can into complex shape parts. Injection molding is suitable for mass production with complex shape products and processing fields.

After a product is designed, usually by an industrial designer or an engineer. Molds are made by a mold maker (or toolmaker) from metal. Usually, either steel or aluminum and precision-machined to form the features of the desired part. Cost savings are highest when components have a minimum wall thickness. As long as that thickness is consistent with the part’s function and meets all mold filling considerations. As would be expected, parts cool faster with thin wall thicknesses. This means that cycle times are shorter, resulting in more parts per hour. Further, thin parts weigh less, using less plastic per part.

On average. The wall thickness of an injection molded part ranges from 2mm to 4mm (.080 inch to .160 inch). Thin wall injection molding can produce walls as thin as .05mm (.020 inch). Injection mold tooling is a very specialized profession requiring highly skilled engineers to create the injection mold tool.

Precision injection molding:

It is to point to the precision of molding parts and surface quality requirements are a very high process. Also, some people think, precision injection moulding is the plastic part of the size accuracy to achieve 0.01 ~ 0.001 mm injection molding process. In recent years, with electronic, medical, communications, automotive, and other industries. With the rapid development of plastic products of high precision, high-performance requirements increasing. The traditional plastic molding process has been difficult to meet the requirements of the current high standards. At the same time, injection molding is one of the most important plastic molding methods. Therefore, precision injection molding technology is getting more and more get the attention from people, make the precision injection moulding technology constantly progress, new technology constantly emerging.

Precision injection moulding for products not only has high dimensional precision, lower buckling deformation, good transfer characteristics. But also should have excellent optical performance and so on. Therefore, it is for injection molding machine, mold, injection molding technology, performance and the formula of raw material and so on all have special requirements, there are many factors which can affect the precision injection moulding.

Precision injection molding requires a high level of accuracy and consistency in the manufacturing process, which can be difficult to achieve. Here are a few reasons why precision injection molding can be challenging:

- High tolerances: Precision injection molding requires extremely tight tolerances, often in the range of microns. Achieving these tolerances requires a high level of precision in the mold design, tooling, and manufacturing process.

- Material properties: The properties of the plastic material being used can impact the precision of the injection molding process. Factors such as viscosity, flow rate, and shrinkage can all affect the final dimensions of the part.

- Mold design: The design of the injection mold is critical to achieving precision in the molding process. The mold must be designed to minimize warpage, shrinkage, and other factors that can affect the final part dimensions.

- Manufacturing process: The injection molding process itself must be carefully controlled to ensure consistent part quality. Factors such as temperature, pressure, and cooling time can all impact the final part dimensions.

Overall, precision injection molding requires a high level of expertise and attention to detail to achieve the desired level of accuracy and consistency.