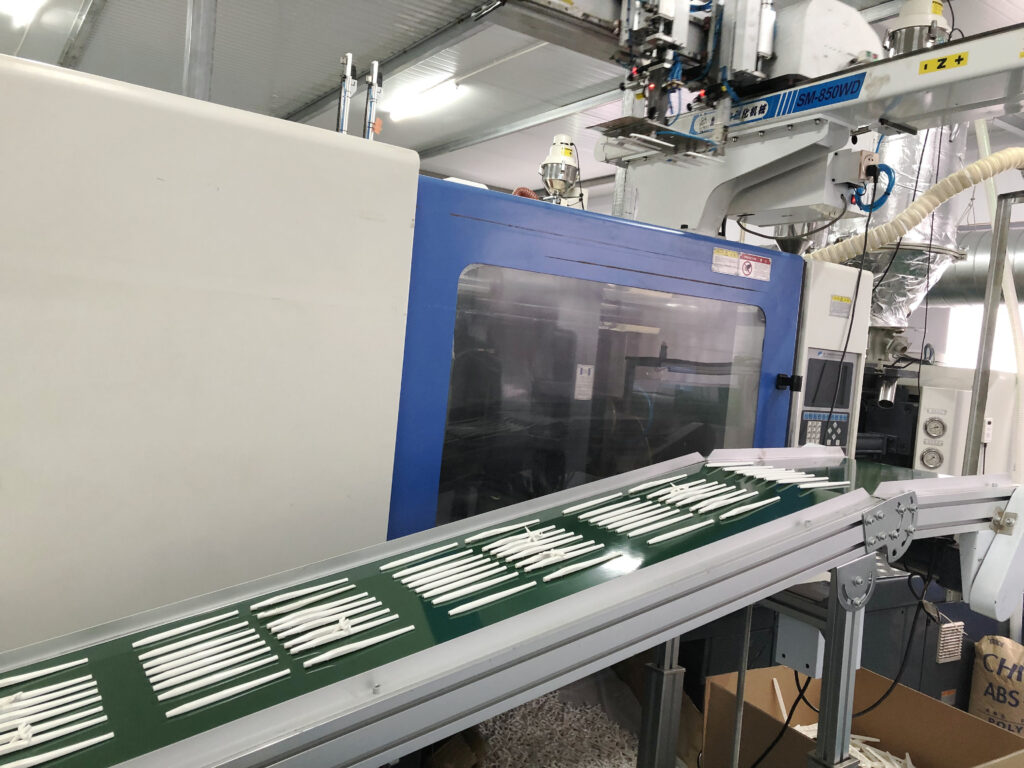

Precision Injection Molding Parts for Medical & Automotive Industries

As a premier injection molding manufacturer based in Shanghai, CNMOULDING specializes in delivering high-precision plastic components that meet the rigorous demands of the Medical and Automotive sectors. We combine decades of engineering expertise with state-of-the-art technology to transform your complex designs into high-quality, market-ready products.

Why Partner with CNMOULDING?

- Medical Grade Excellence (ISO 13485 Compliance):

We understand that in the medical field, precision saves lives. Our facility is equipped to handle medical-grade polymers, ensuring biocompatibility and consistency for surgical instruments, diagnostic devices, and laboratory consumables. Our rigorous IQ/OQ/PQ validation processes guarantee every batch meets healthcare safety standards.

- Automotive Performance (IATF 16949 Standards):

The automotive industry demands durability and tight tolerances. CNMOULDING provides robust solutions for engine components, interior trims, and electronic sensor housings. We specialize in Insert Molding and Overmolding, helping Tier 1 and Tier 2 suppliers achieve lightweighting goals without compromising structural integrity.

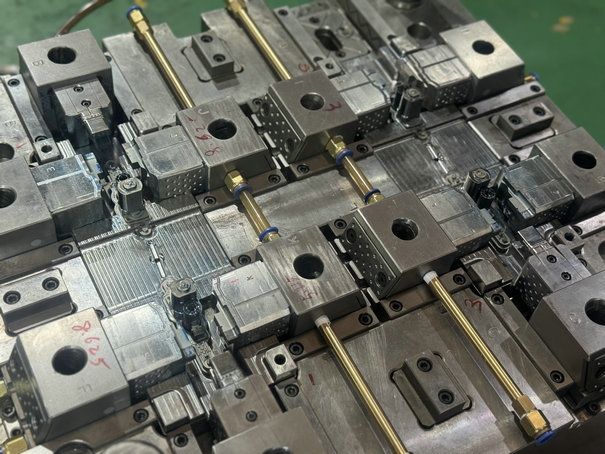

- DFM-Driven Engineering:

Every project starts with a comprehensive Design for Manufacturing (DFM) analysis. We identify potential sink marks, warping, or gating issues before the mold is cut, saving you time and reducing production costs by up to 20%.

- Advanced Material Expertise:

From high-heat resins like PEEK and PPS to transparent materials like PC and PMMA, we have the processing knowledge to handle engineering-grade plastics required for extreme environments.

Our Capabilities at a Glance:

Tolerances: Up to ±0.02mm for critical dimensions

Cleanroom Production: Class 100,000 controlled environments for medical parts.

Rapid Prototyping: T1 samples delivered in as little as 15–25 days.

Scalability: From low-volume bridge tooling to high-volume multi-cavity production

No related posts.