High-Precision Automotive Molding Solutions: From Concept to Mass Production

Supporting automotive OEMs and Tier 1 suppliers with ISO9001 certified manufacturing, advanced lightweighting solutions, and zero-defect quality control.

ISO9001:2015 Certified: A rigorous quality management system specifically for the automotive supply chain.

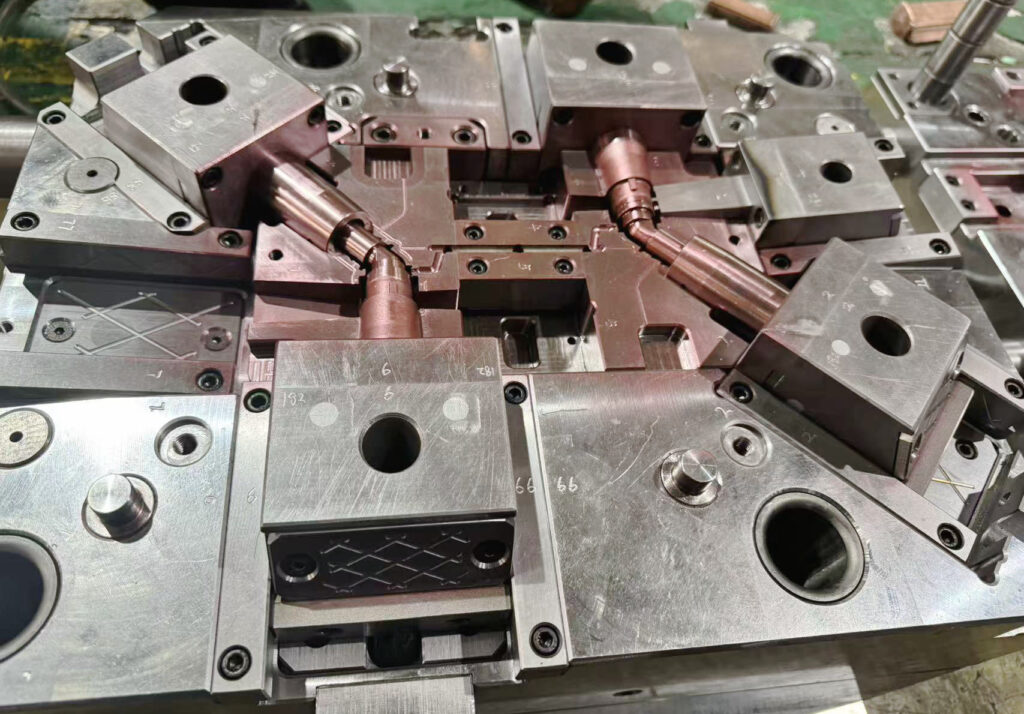

Advanced Moldflow Analysis: We provide detailed simulation reports (filling, packing, cooling, warping) before steel cutting to minimize engineering changes (ECRs).

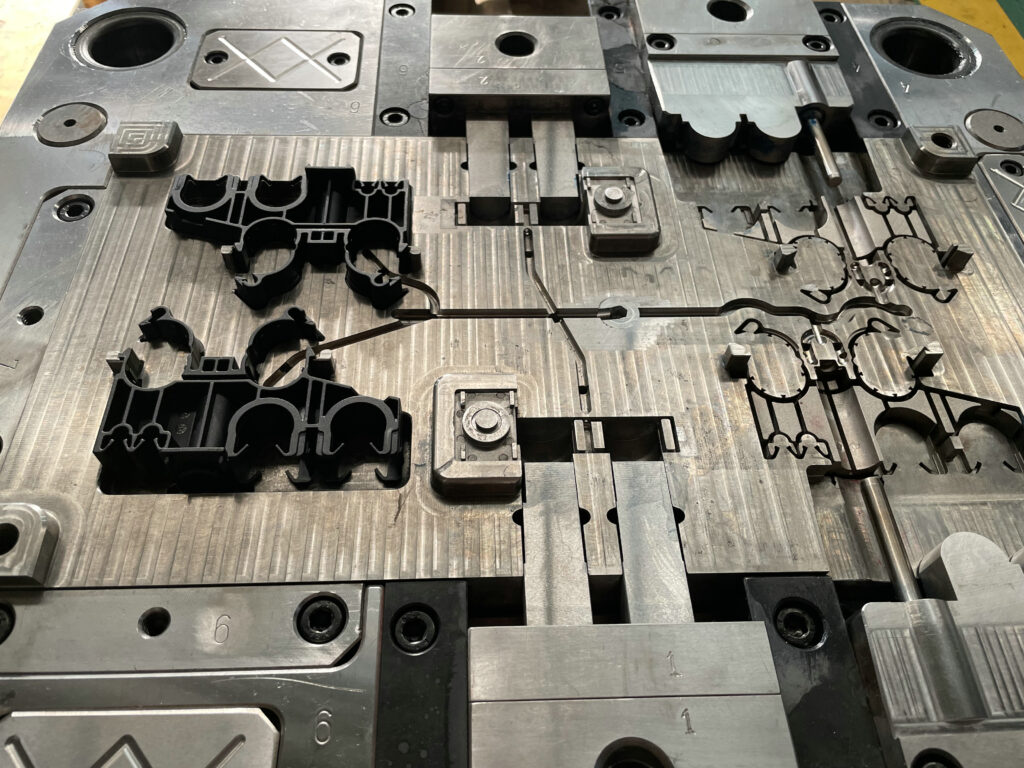

Complex Molding Techniques: Expertise in Insert Molding, Overmolding, and Two-Shot (2K) Molding for multifunctional parts.

Metal-to-Plastic Conversion: Helping clients reduce vehicle weight and cost by redesigning metal assemblies into high-strength plastic components.

Interior & Exterior Trims: Air vents, door handles, dashboard components, and decorative bezels.

Under-the-Hood: Cooling system connectors, engine covers, and oil pans using high-heat resins (PA66+GF, PPA).

Electronic & Sensor Housings: Precision enclosures for ADAS sensors, ECU covers, and EV battery components.

Lighting Systems: High-clarity lenses and reflectors with mirror-finish polishing.

We optimize your TCO (Total Cost of Ownership) through:

High-Speed Machining: Ensuring rapid tool builds and precise tolerances.

Automated Production: Robotic arm integration for consistent cycle times and reduced labor costs.

PPAP Documentation: Providing full Level 3 PPAP packages, including CPK/PPK studies and bubble drawings.0

No related posts.