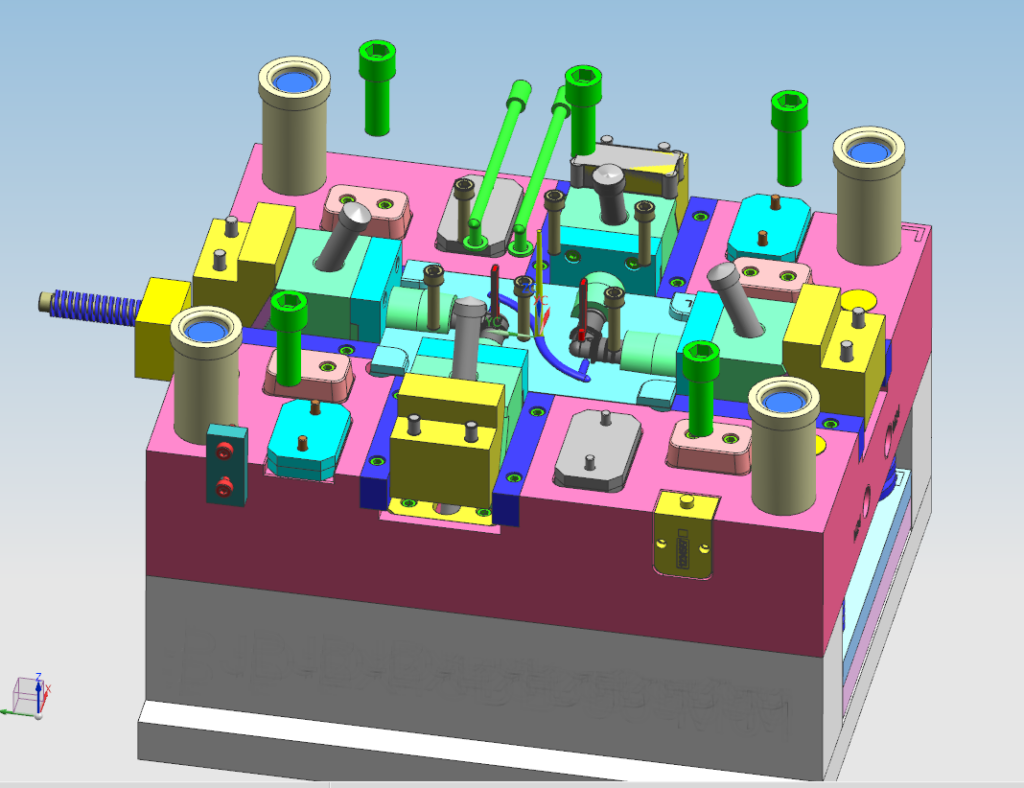

- Injection molds design

- hot runner system

- Solidworks software

- medical mold project

- Product description: Custom injection molds design services – Rapid prototypes molds, injection molding. plastic thermoforming, low prices fast turn around in Shanghai, China

Precision Injection Mold Making & Tooling Solutions in China

Welcome to CNMOULDING’s mold manufacturing center. We specialize in providing custom plastic injection molds designed to meet the rigorous standards of North American and European markets. Whether you require a single-cavity prototype or complex multi-cavity production tooling, our engineering-driven approach ensures high-performance results.

Key Technical Capabilities:

Standard Compliance: Fully compatible with DME, HASCO, and LKM standards.

Tooling Precision: In-house high-speed CNC and Mirror EDM achieving tolerances within ±0.005mm.

Diverse Mold Types: Expertise in 2-Plate/3-Plate molds, Overmolding (2K), Insert molding, and Unscrewing molds.

Rapid Lead Times: T1 samples delivered in as little as 25 days with comprehensive DFM (Design for Manufacturability) reports.

Our ISO 9001:2015 certified process integrates advanced MoldFlow analysis with meticulous craftsmanship, ensuring your mold is optimized for cycle time efficiency and long-term durability. Partner with us to reduce your tooling investment by up to 50% without compromising on precision.

mold design

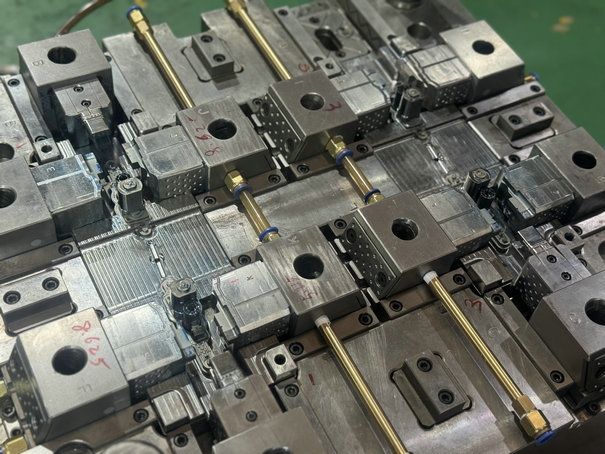

Chinese injection mold essentials

- Essentials

- Injection mold making

- 500usd Minimum Only

- 15 days

- Product description: Essentials of China injection mold company, for screw, thickness, locating pin and ring, bushing, groove, sleeve, cooling, pipe, and slider.

Medical Mold

- Medical Injection mold

- Medical plastic mold

- 1000USD start

- 20 days Minimum

- Product description: Medical Plastic Mould at Injection Mold china.com,we provide you precision plastic injection mold solutions for your medical manufacturing project

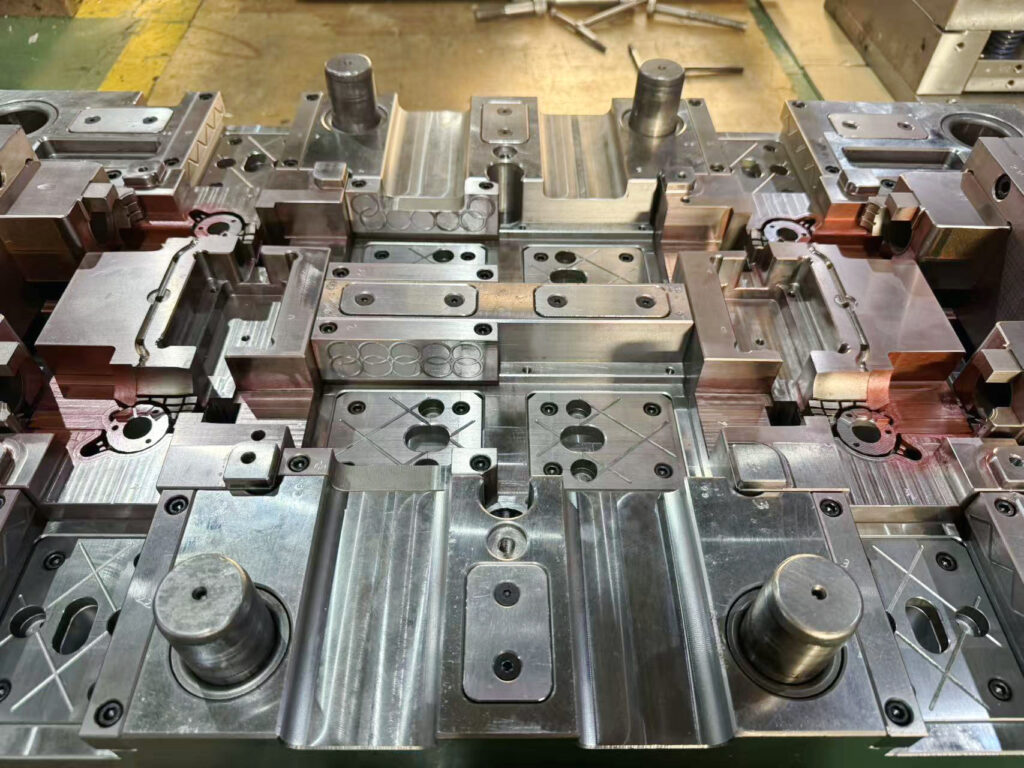

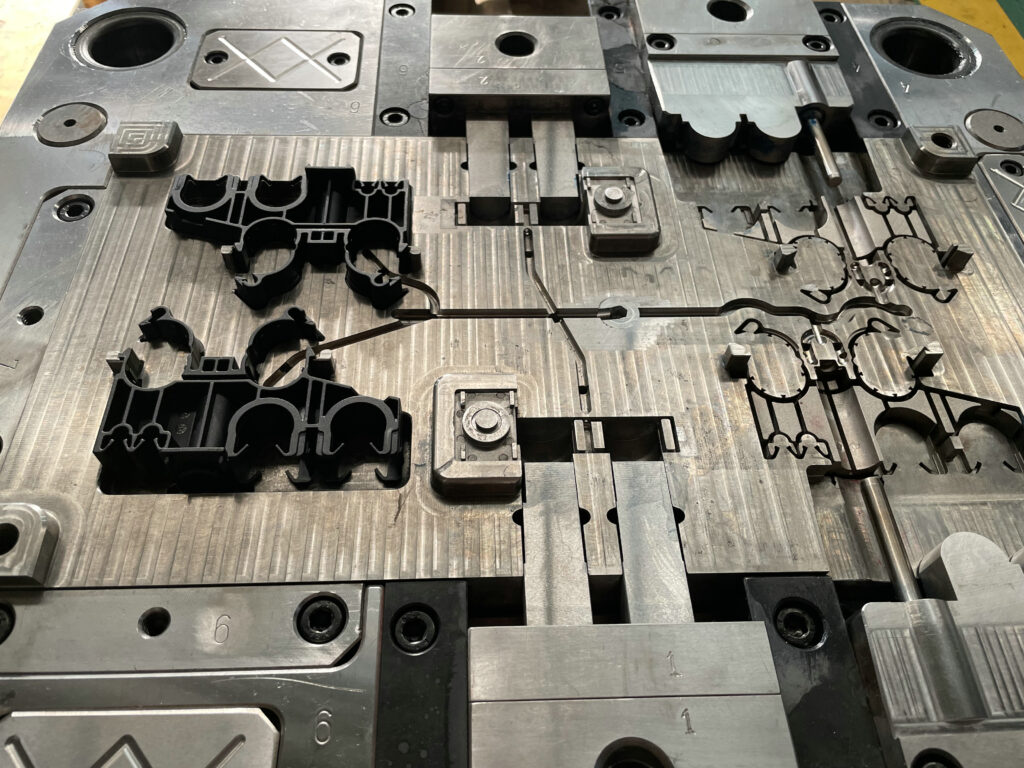

China Injection Mold Making Slider structure

- Slider structure

- Injection Mold

- Plastic Mould

- In China

- Product description: China injection mold company specializes in plastic injection mold and injection moulding products for slider structure

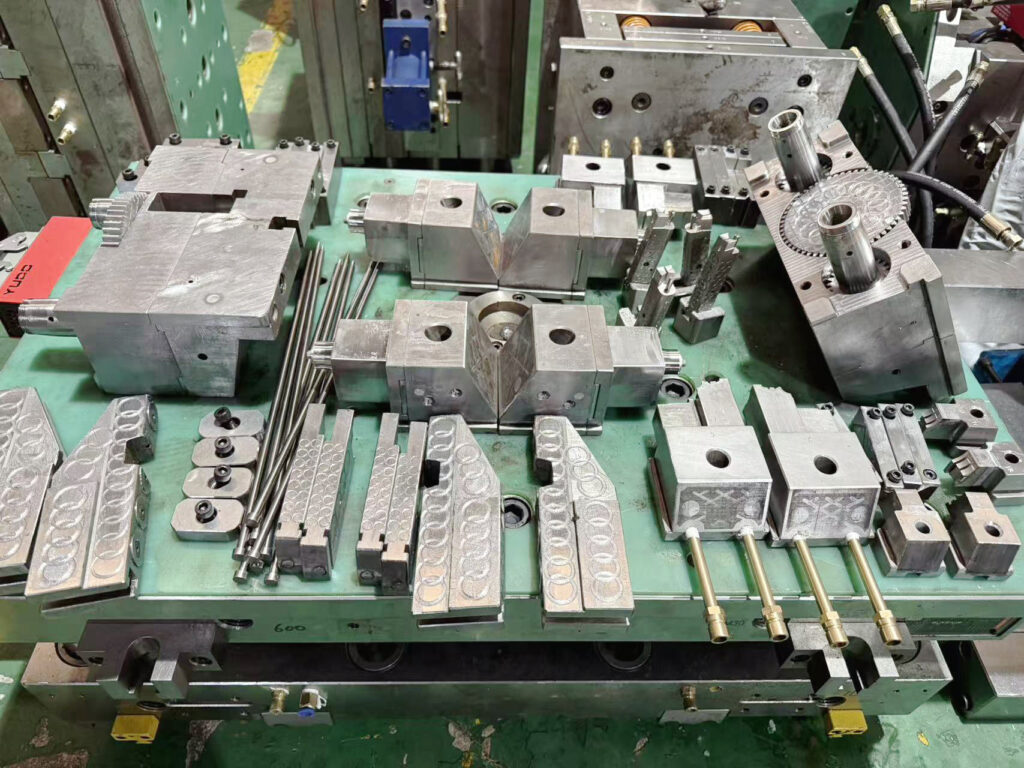

Injection mold maintenance and repair

pre-production mold maintenance:

1 must be on the surface of the mold of oil, rust clean, check the mold cooling water hole for any foreign body, the waterway is smooth.

2 mold fixed template screws and clamping clips are tightened;

Two-color plastic injection mould

Cost of customized injection mold

Injection molding is the most common method of production, with some commonly made injection molded items including computer components to outdoor furniture

Automotive Plastic Mould

As we know, the auto business develops very quickly in the past ten years, more and more newest go to the market, lots of automotive components are made from plastic, which means it needs a large number of molds made.

CNMOULDING-injection mold

CNMOULDING-injection mold company offers a plastic injection molding service and specializes in various plastic molds. automotive, home appliances, electronics, as well as general industrial OEM applications.

injection mold principleI

- Injection Mold

- Plastic Mold

- China company

- China manufacturer

- Product description: Cn-moulding is a trustable and professional plastic injection mold manufacturing company in China

Our Specialized Mold Making Categories

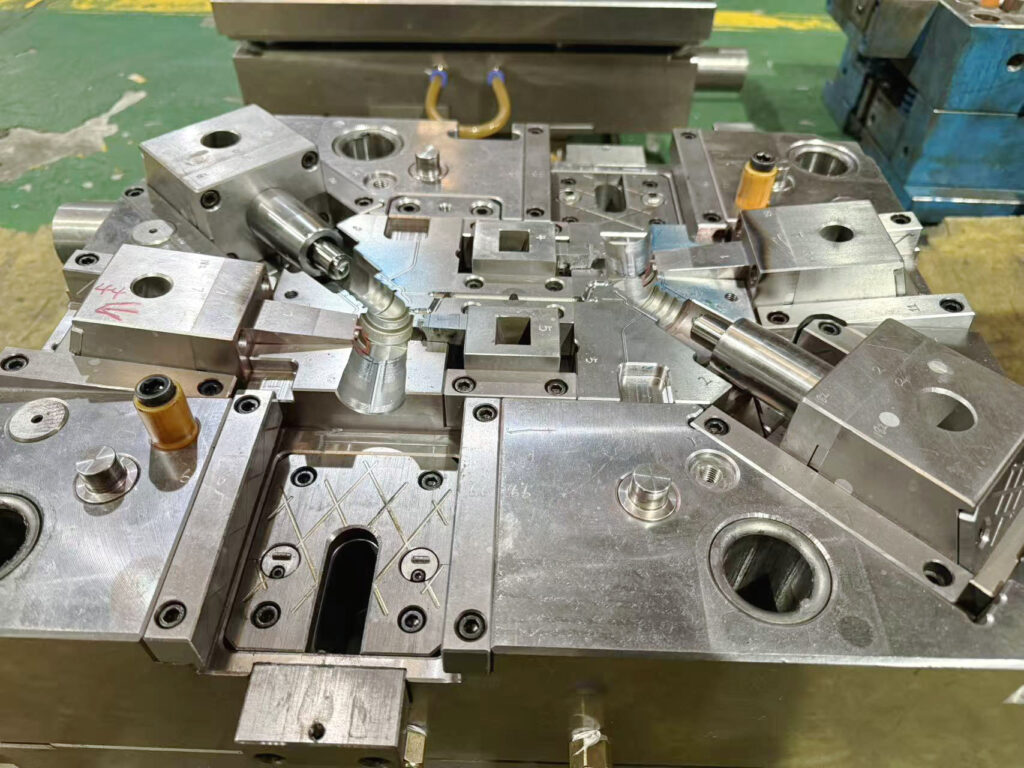

1. Automotive & Industrial Precision Molds

We engineer robust injection molds for the automotive industry, ensuring high durability and tight tolerances. From interior trim components to functional engine parts, our tools are built to withstand high-volume production cycles.

Key Features: Hot runner systems (Yudo/Mold-Masters), complex slider/lifter mechanisms, and high-strength mold steel (S136, H13).

Typical Parts: Air vents, door handles, gear shift housings, and connector housings.

2. Medical & High-Precision Electronic Molds

For industries requiring zero-defect production, we offer high-precision tooling with clean-room compatibility in mind. Our focus is on dimensional stability and aesthetic perfection.

Key Features: Multi-cavity designs (up to 48 cavities), mirror polishing (SPI A1/A2), and high-speed cycle optimization.

Typical Parts: Syringe components, medical device housings, precision gears, and smartphone connectors.

3. Overmolding (2K) & Insert Molding Solutions

Expand your product’s functionality with our advanced overmolding techniques. We specialize in bonding TPU/TPE with rigid substrates (ABS/PC) to create soft-touch grips and multi-material designs.

Key Features: Expertise in vertical and horizontal overmolding, complex insert loading, and chemical bonding optimization.

Typical Parts: Hand tool grips, waterproof seals, and ergonomic electronic enclosures.